Main Objective

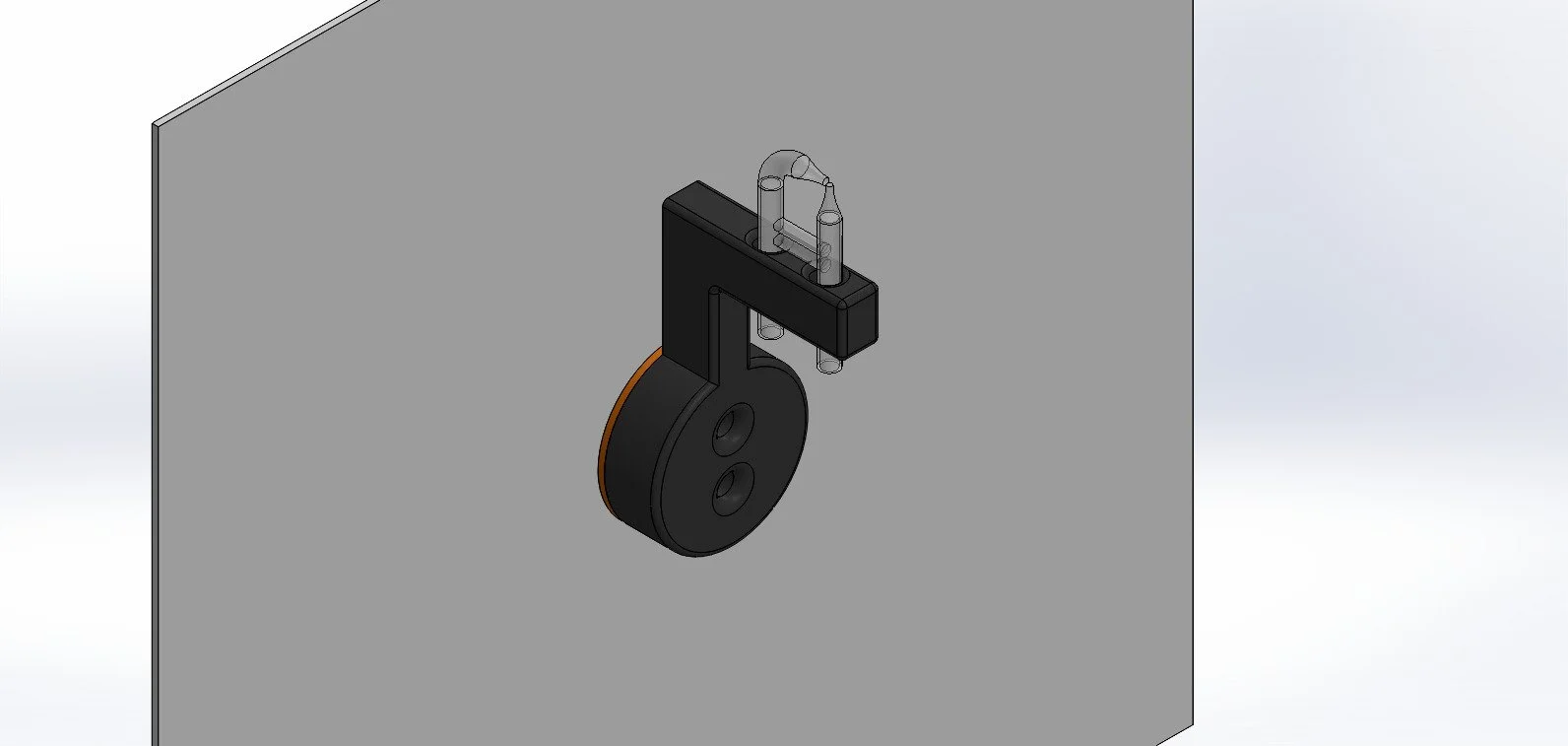

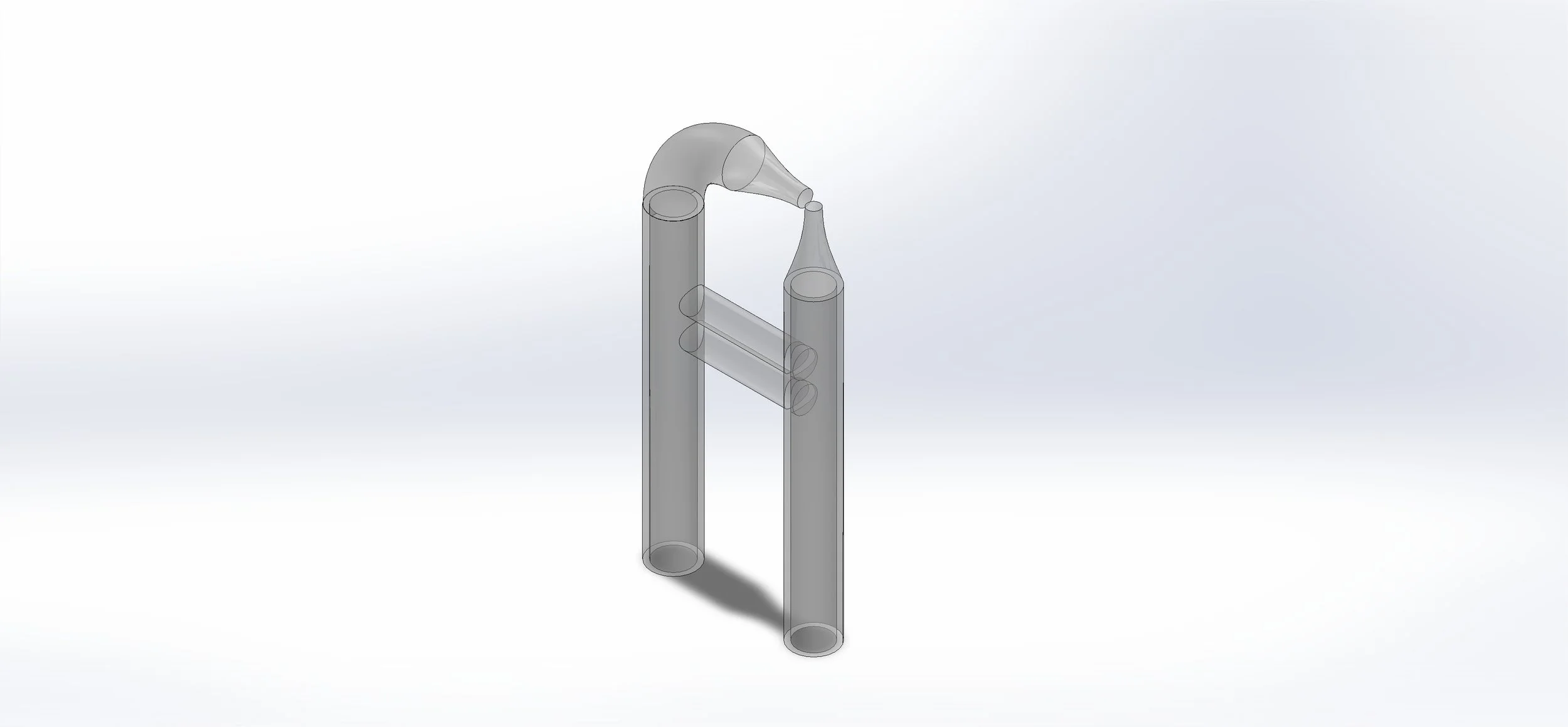

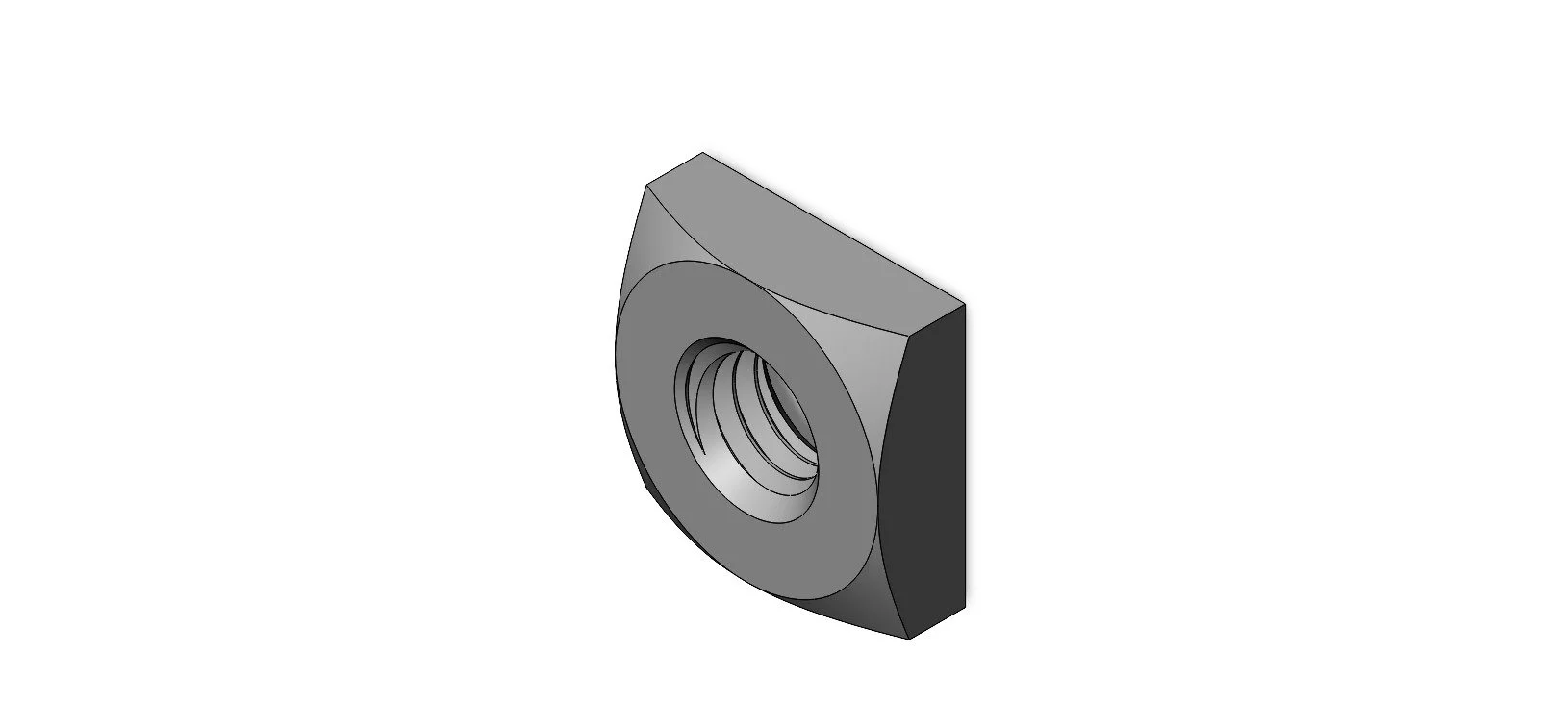

Bemco Inc. has updated their previous salt spray nozzle from an in house manufactured adjustable assembly to a one piece glass siphoning nozzle. This more ideal nozzle must be met by an ideal mounting solution that adheres to ASTM B 117 and MILSPEC 810. Meaning that the part will be exposed to salt water for long periods of time and must create a seal that does not let salt water fog escape the chamber.

Prior Set Up

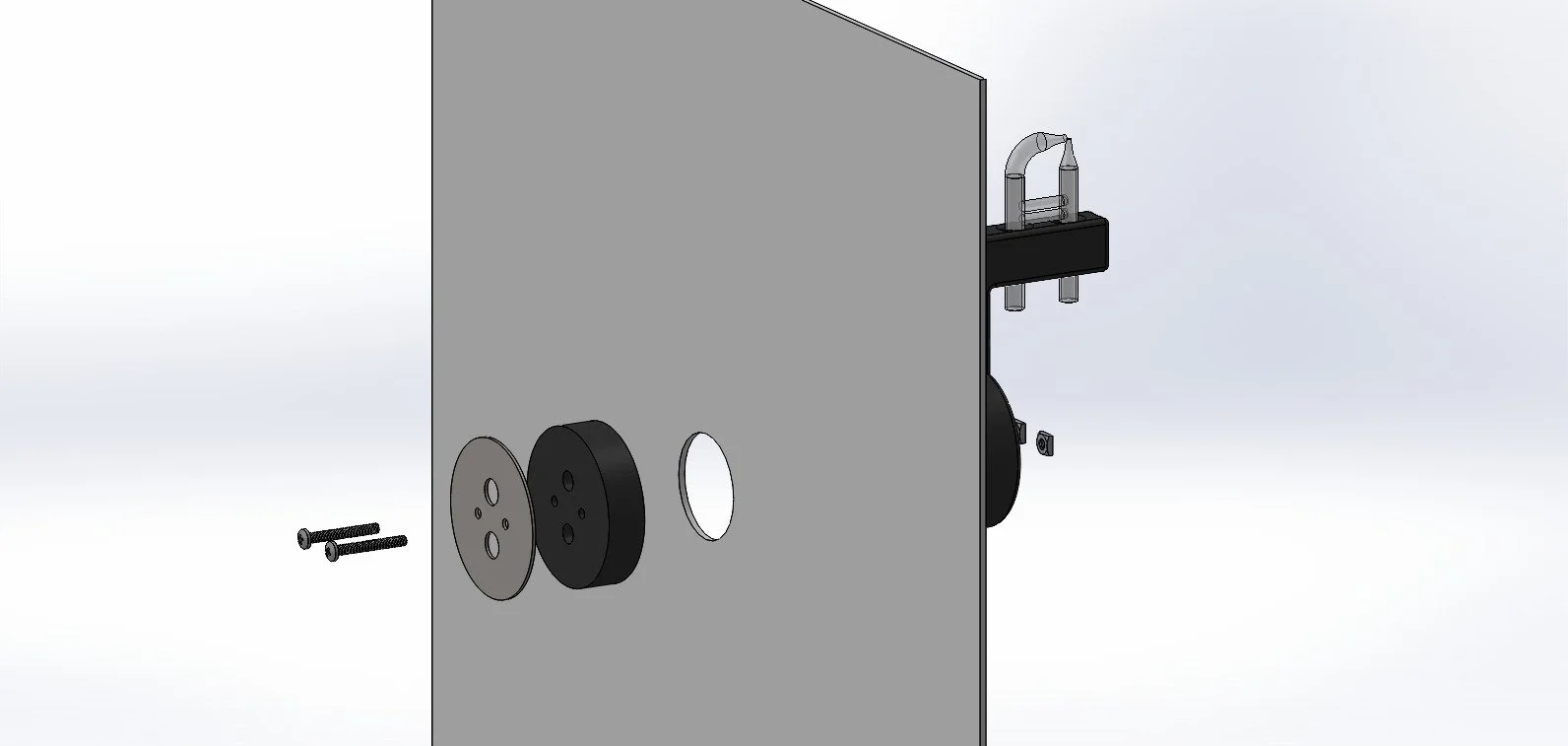

The ASTM B 117 and MILSPEC 810 state that corrosive resistant materials are to be used in the testing space. Although Stainless Steel presents corrosion resistance, Bemco Inc. specified no metallic materials shall be in the salt spray apparatus. The prior design for the new nozzle uses stainless steel screws, relies on an unreliable seal and mounting system, and lacks an aesthetic quality.

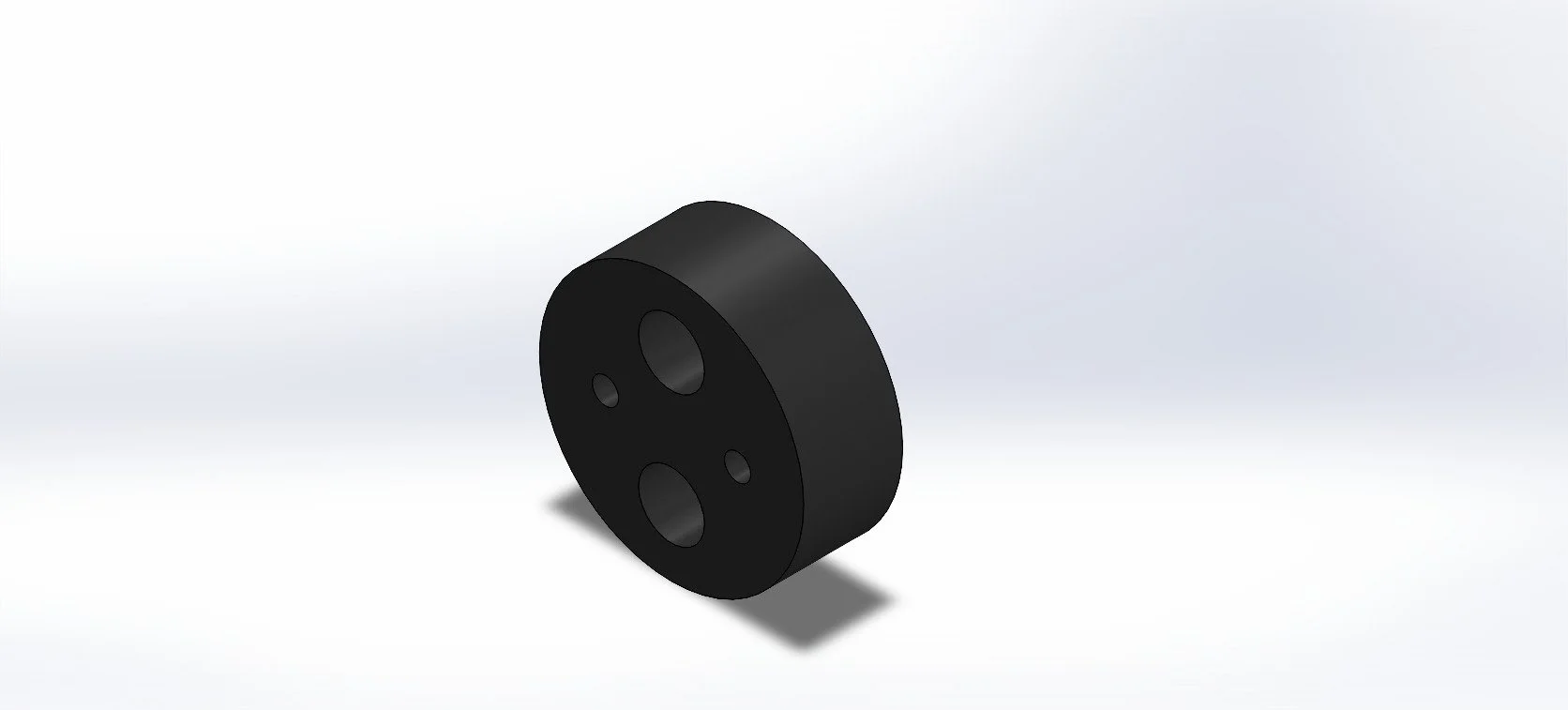

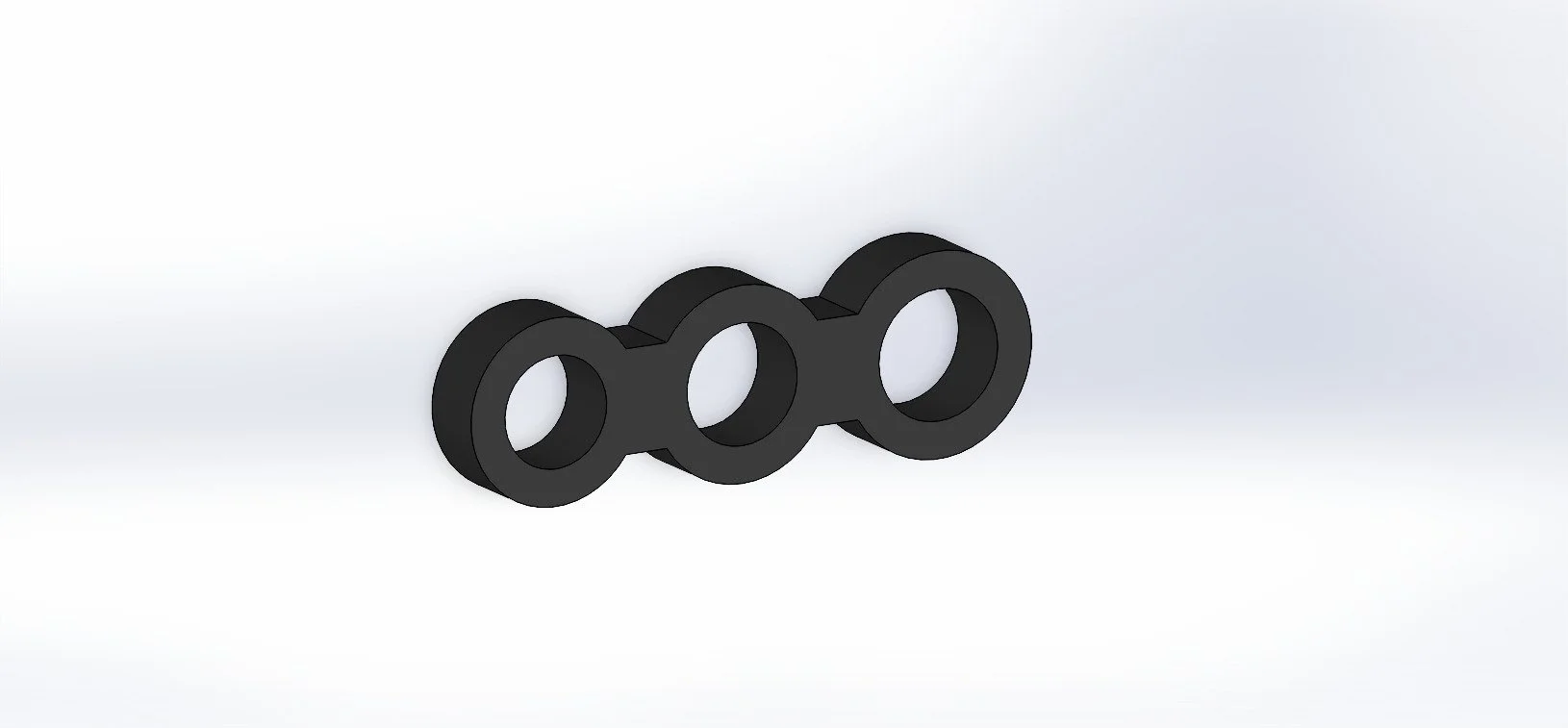

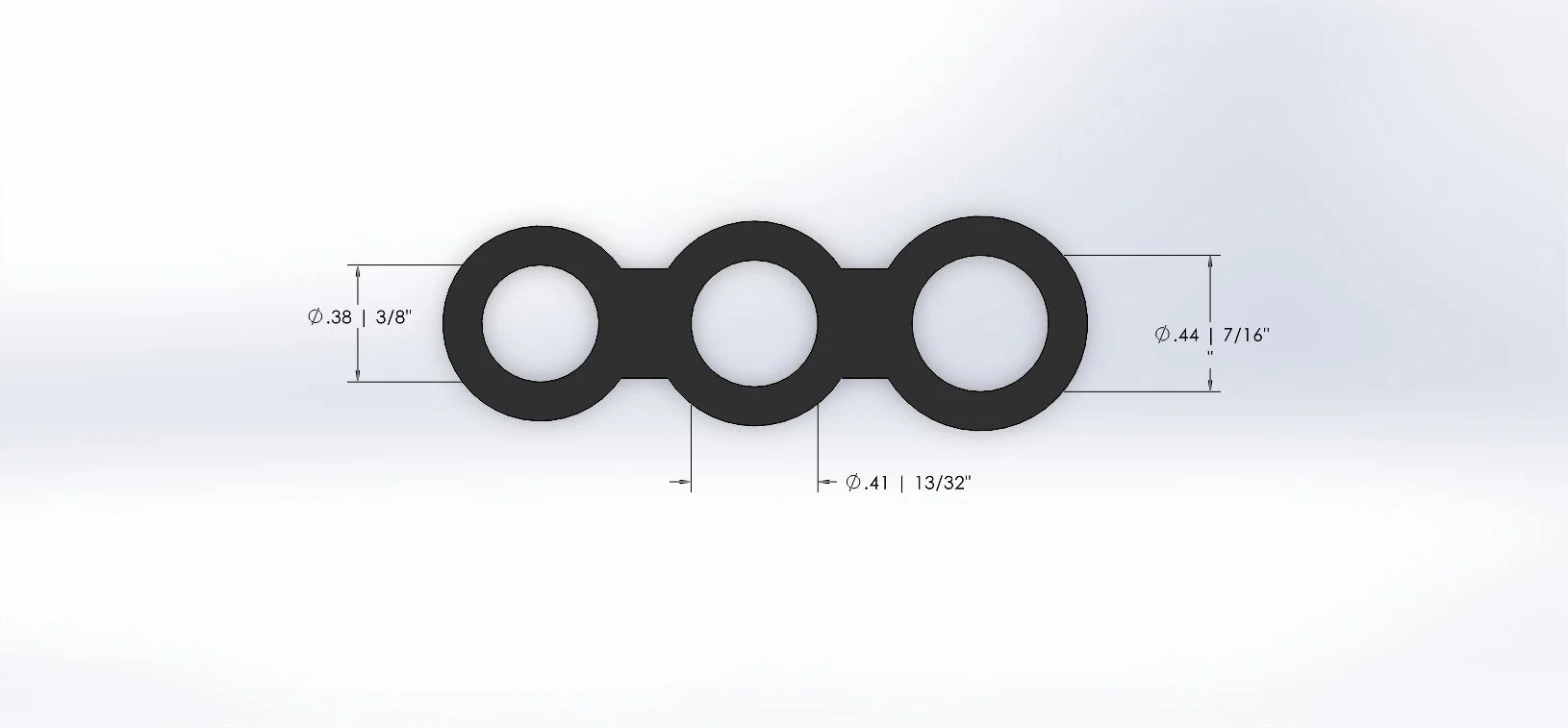

Tubing Test Fit

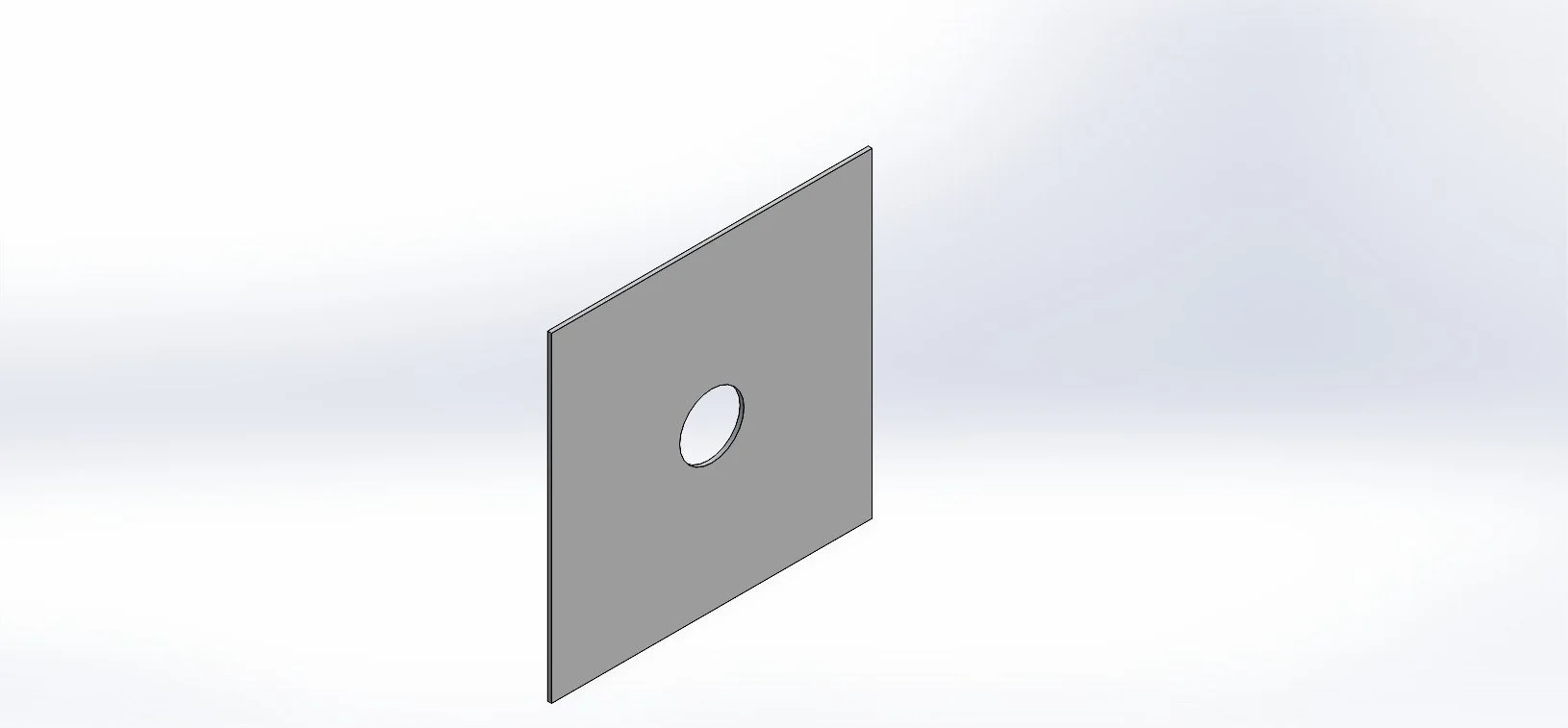

Test tolerances of the Bambu X1C 3D Printer as well as what would provide the best fit to create a seal using Polymax PETG Black - the same filament as the main assembly where the tubing will be guided through.

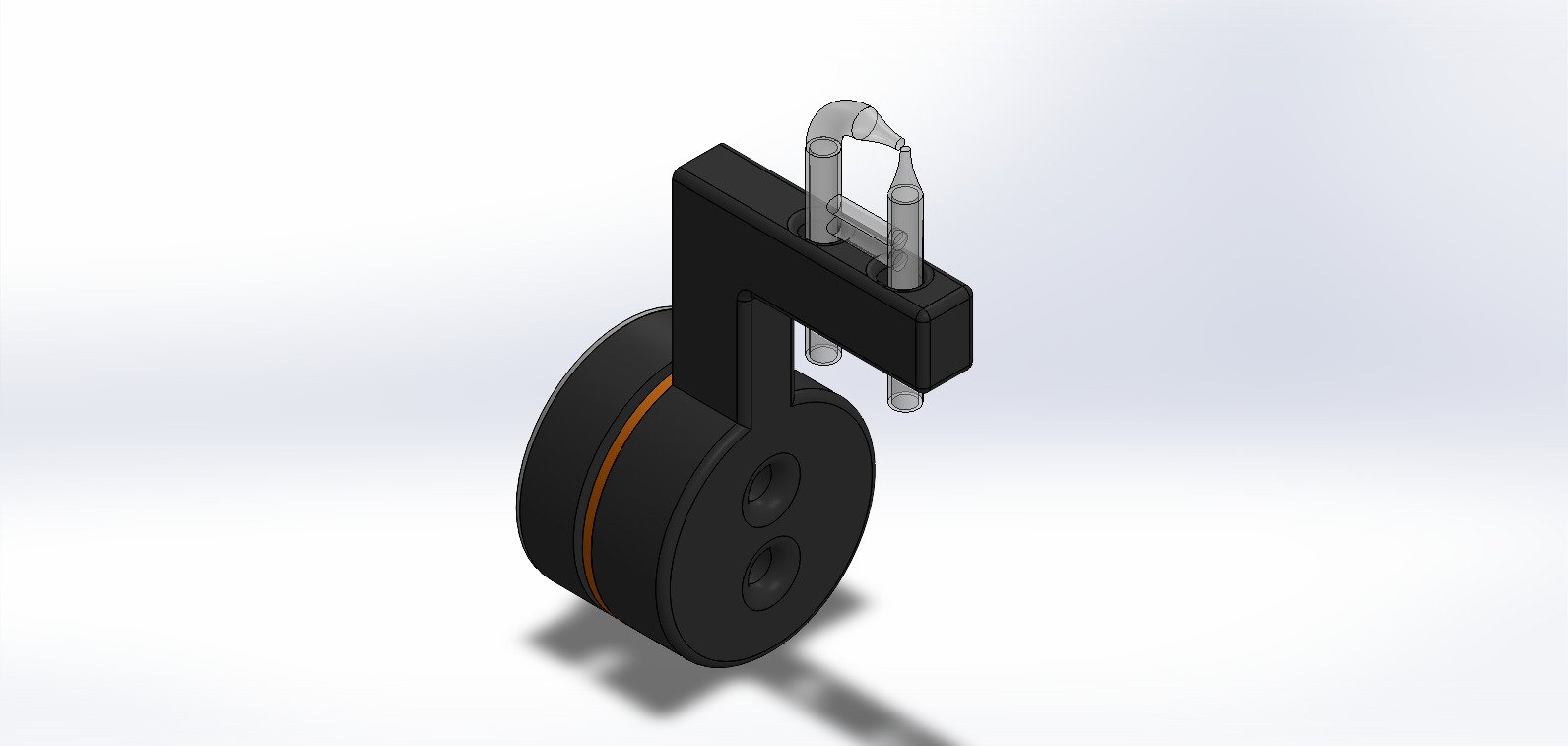

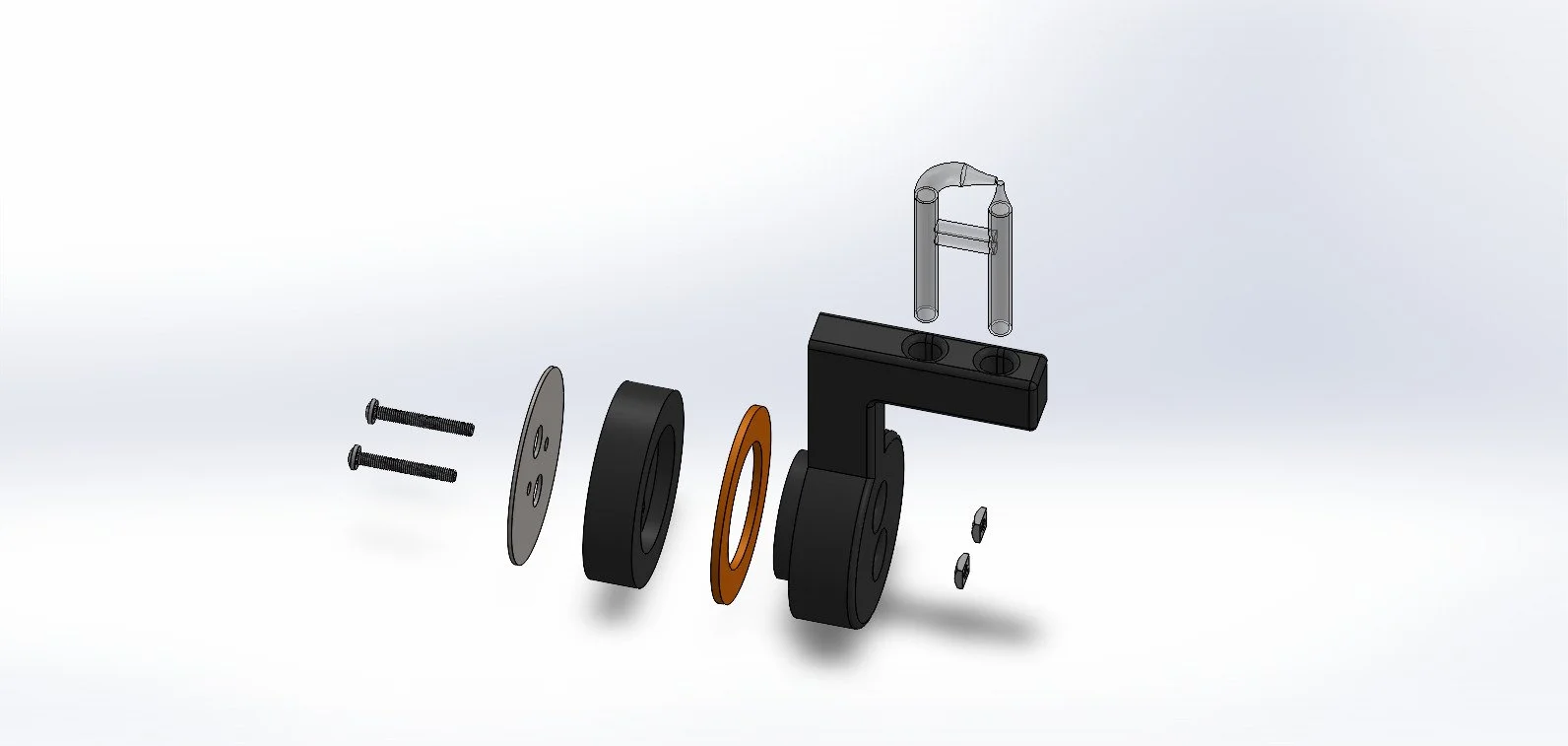

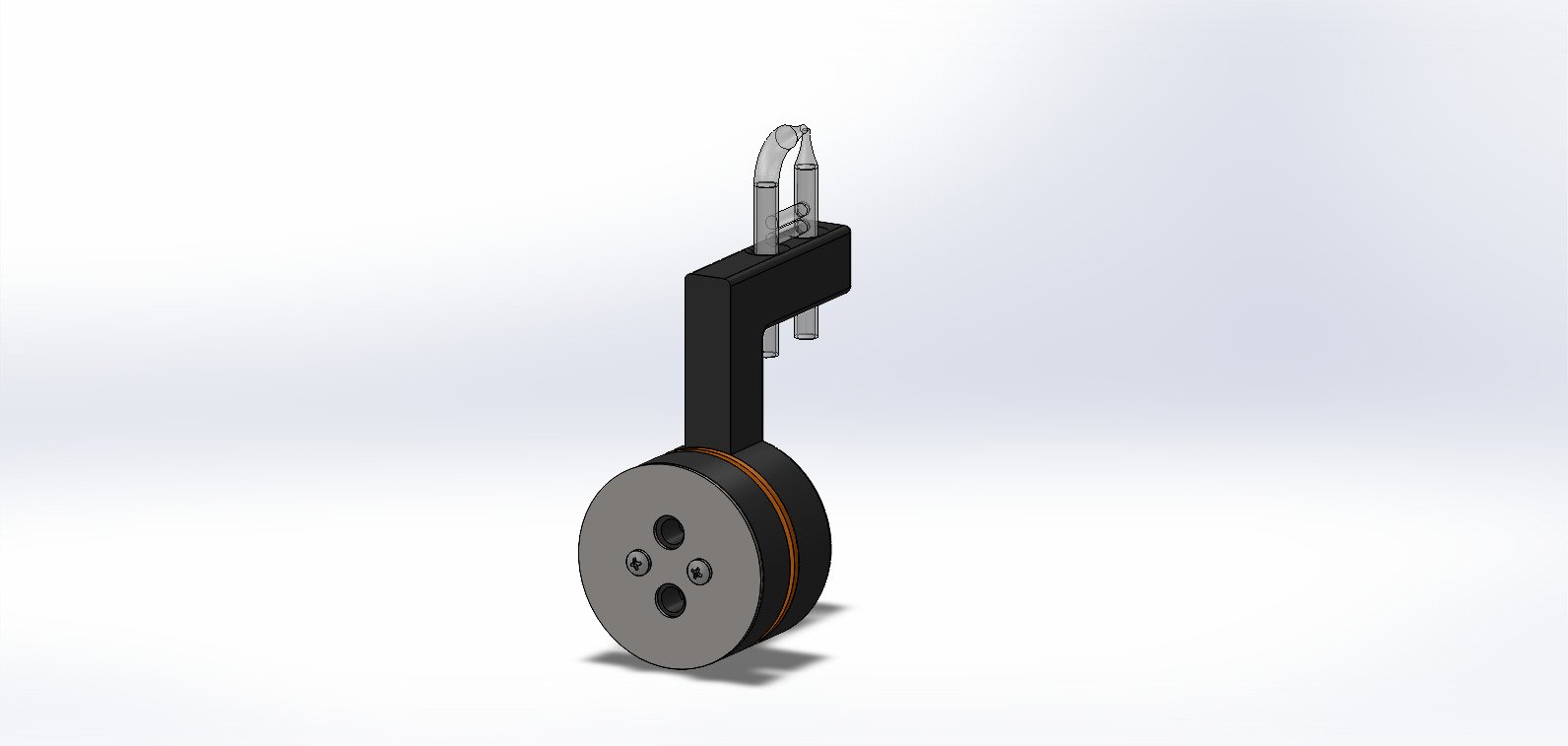

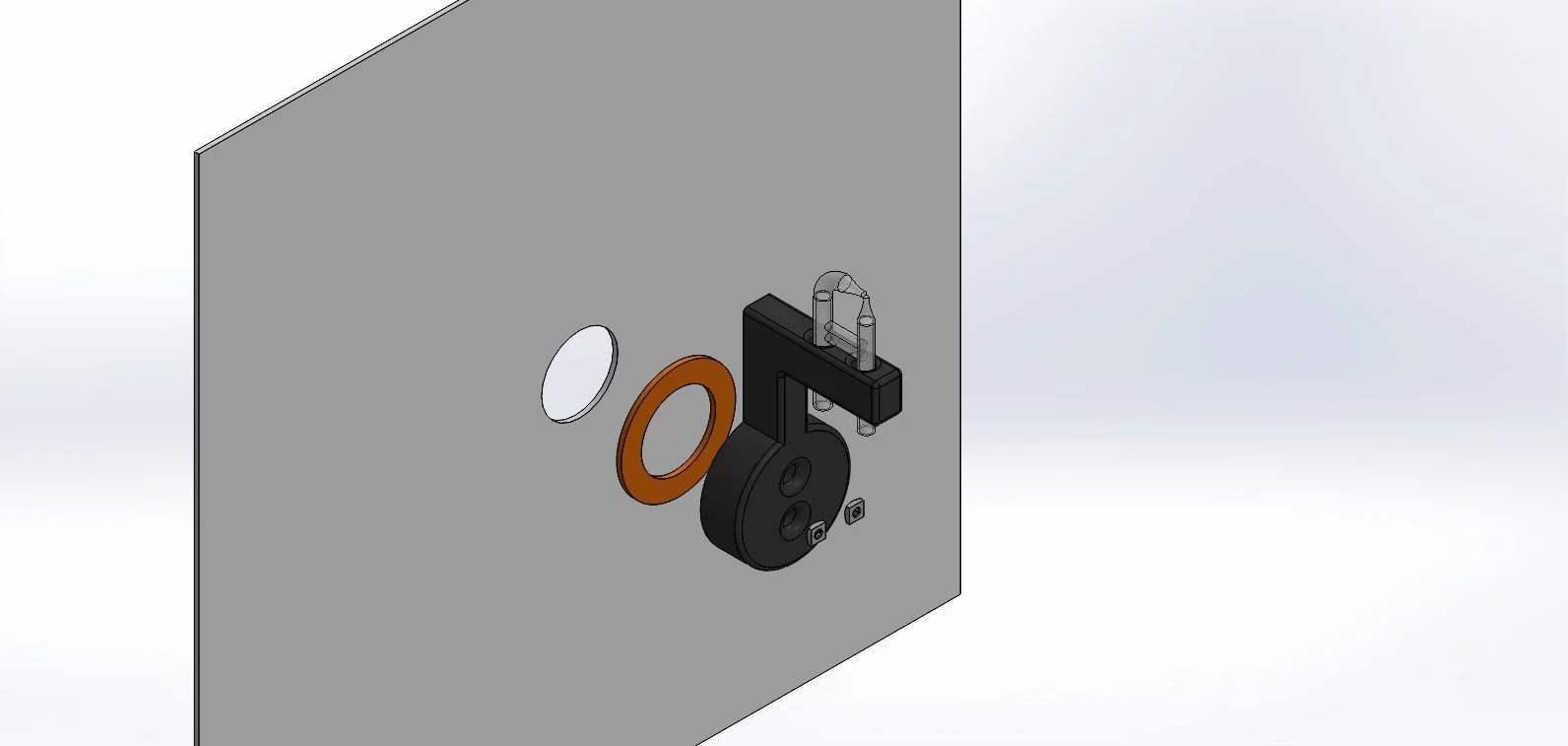

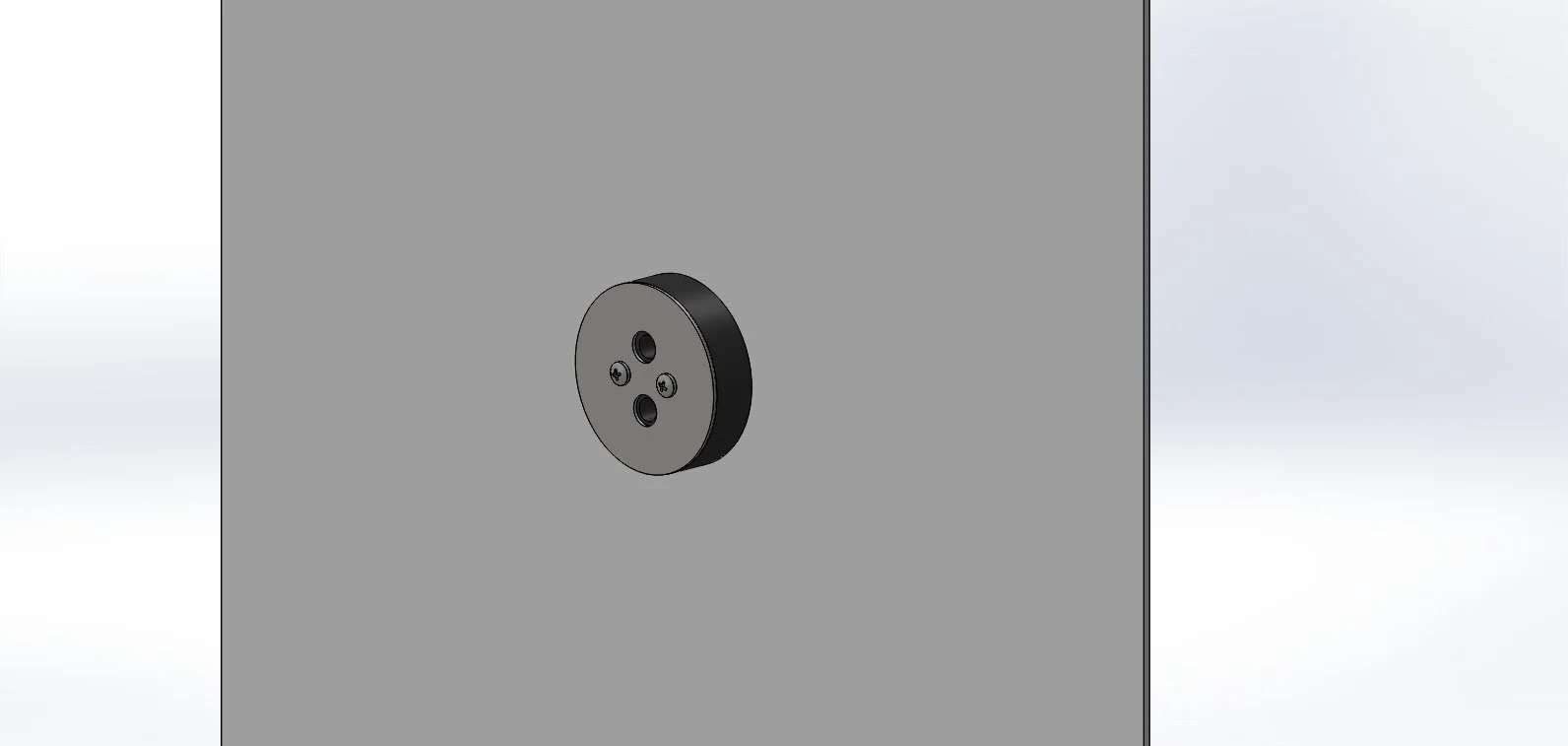

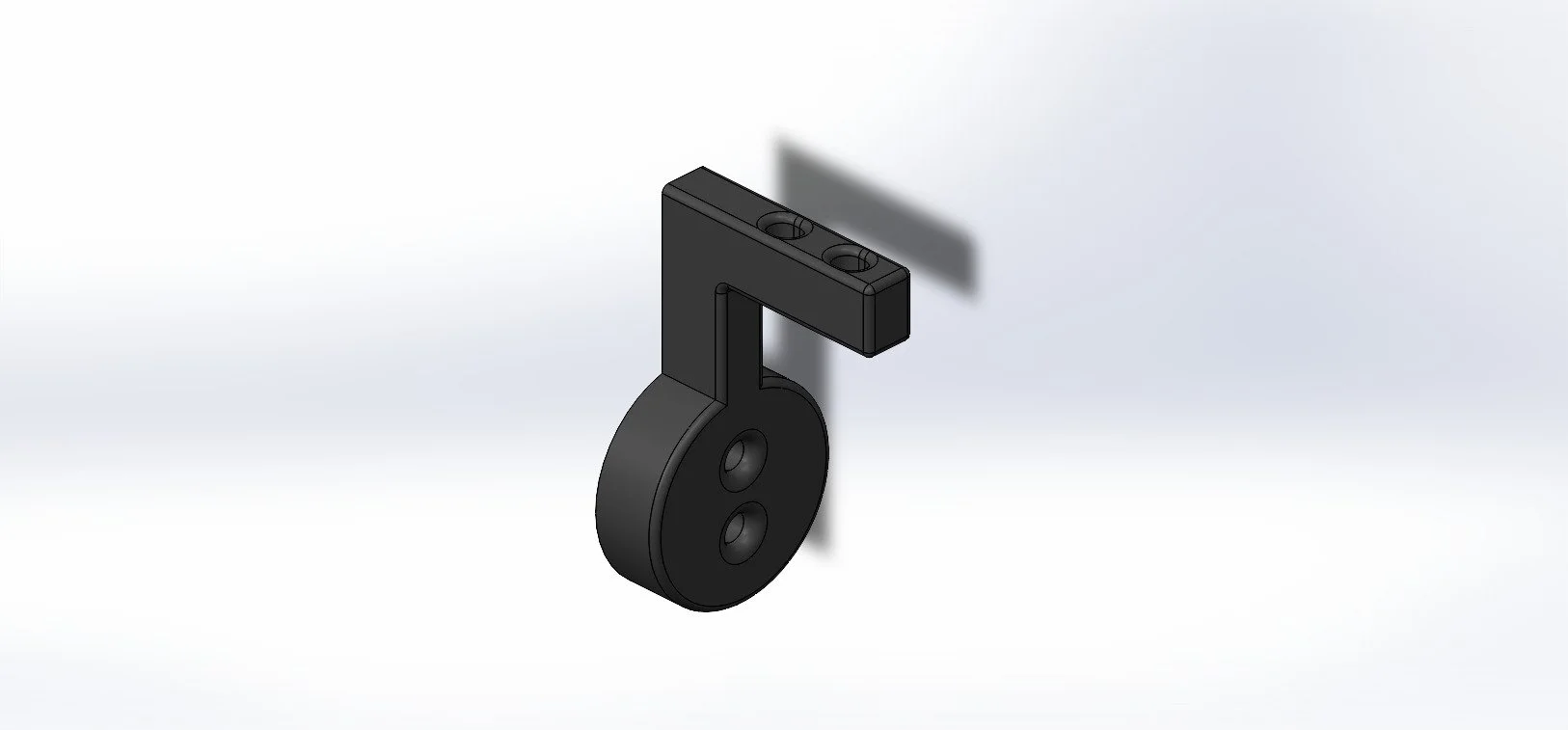

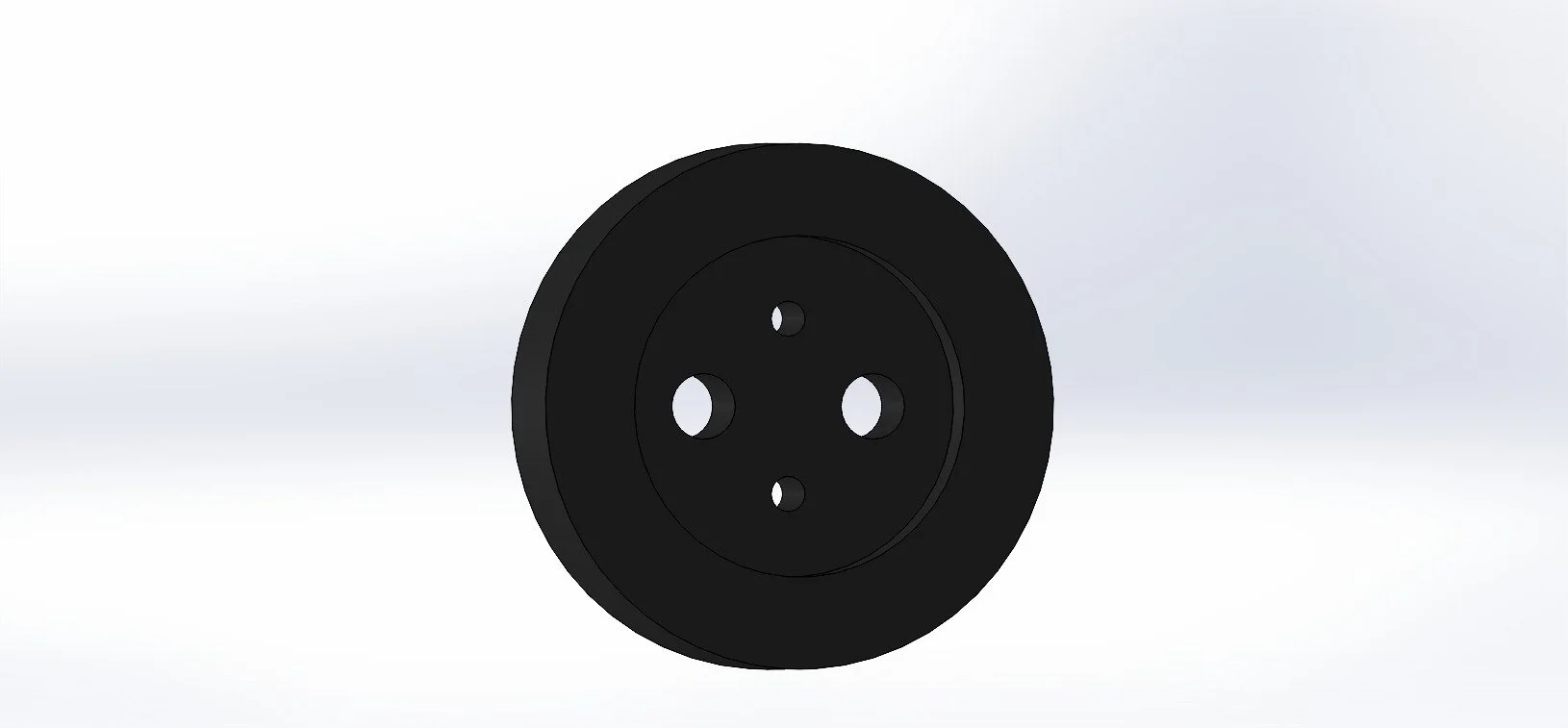

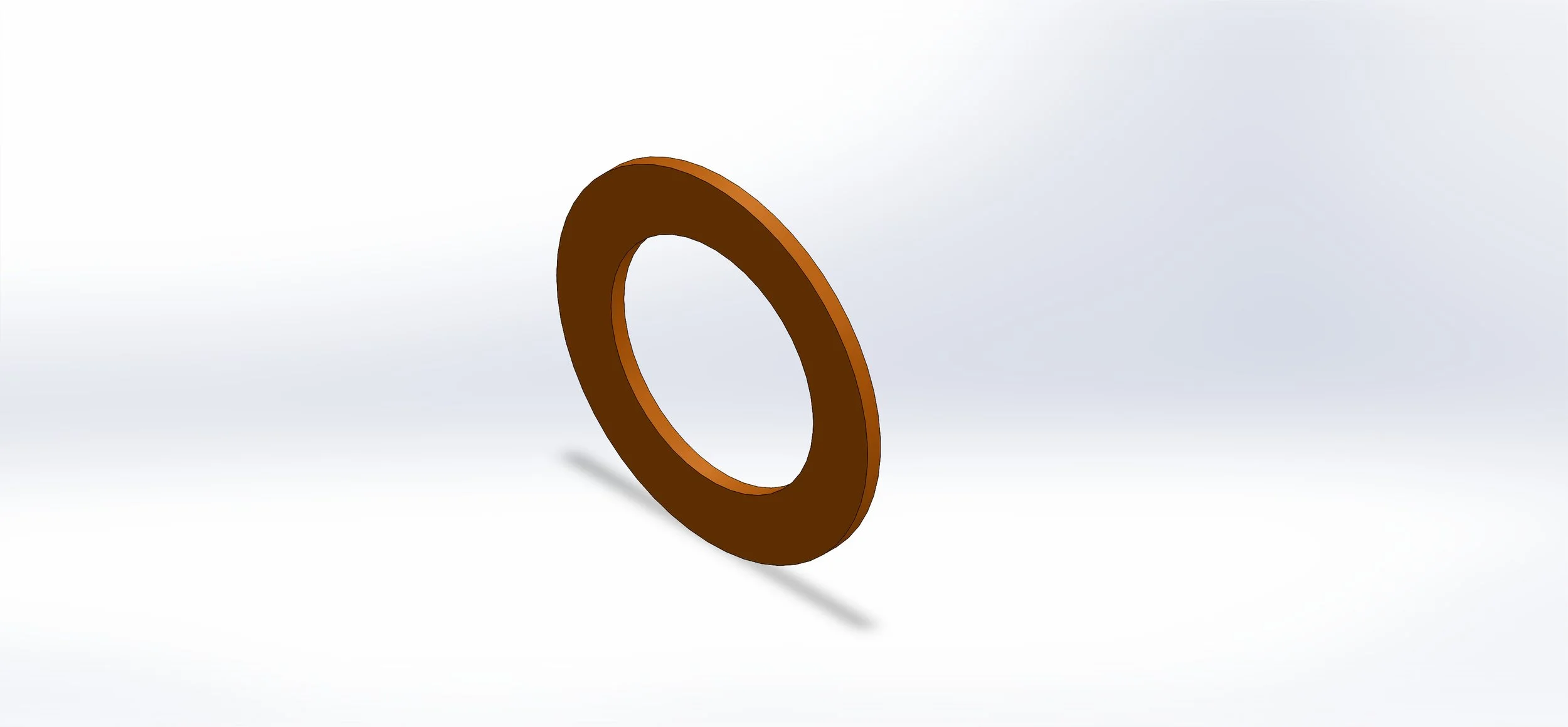

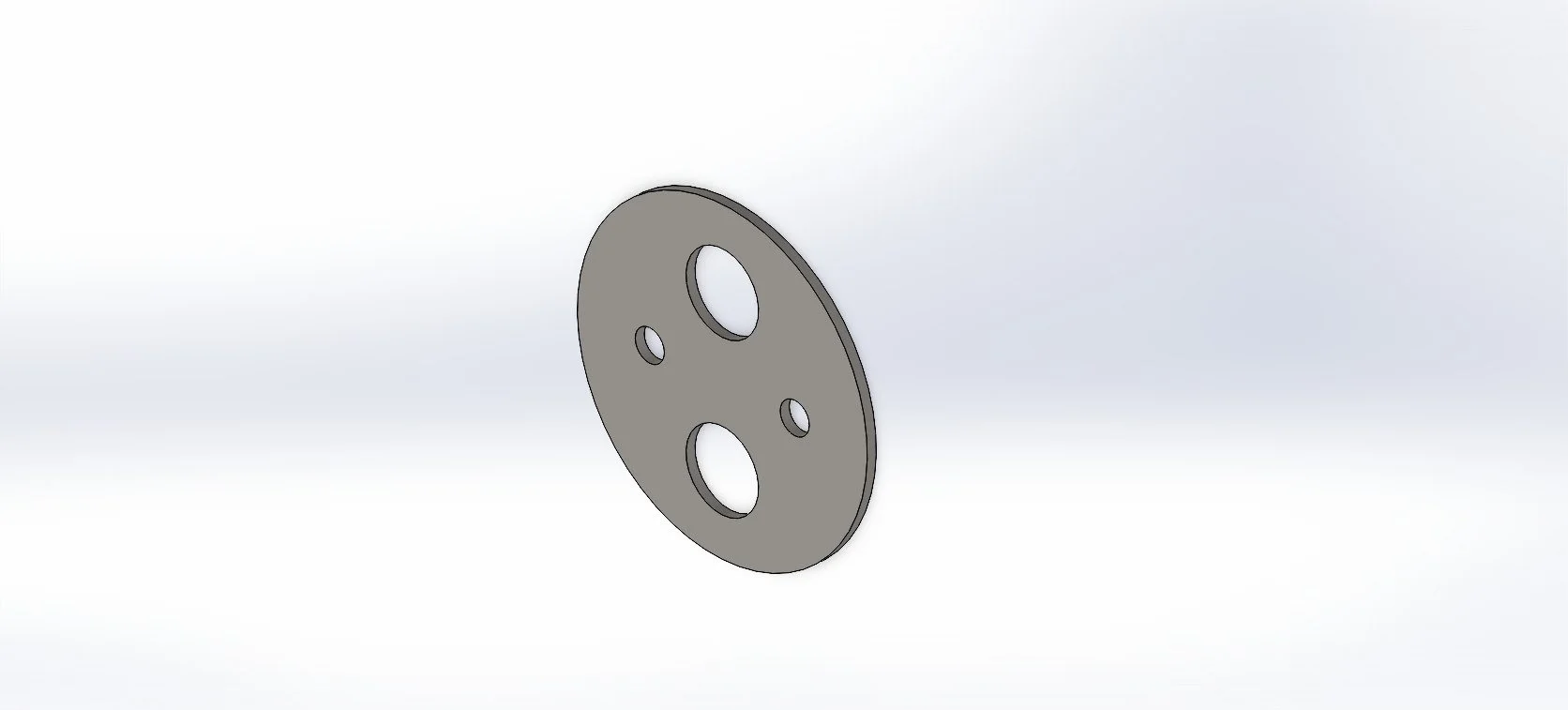

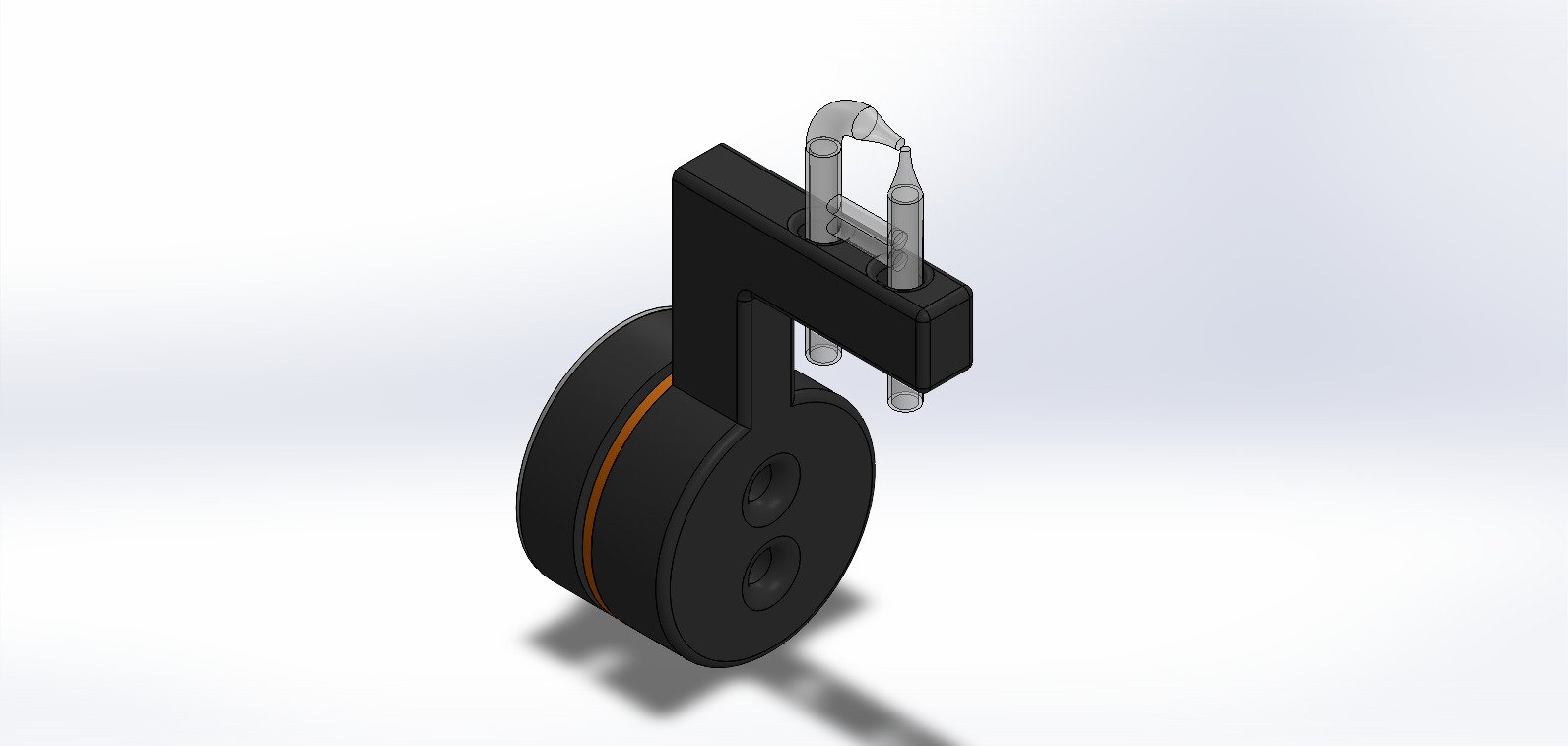

Mounting Solution

The final mounting solution features a tested reliable seal along with Polymax PETG material. An extra layer of resistance was added to the 3D printed parts in a silicone sealant spray.

Corrosive Testing

Testing was conducted with the appropriate amount of salt to water ratio specified in ASTM B 117. The Bemco Inc. chamber was set to internal temp of 100F. This is 5F above what the components in the salt spray chamber should experience. The nozzle mount was untreated via the silicone spray and was printed with the standard Polymax PETF filament. The test was conducted for 1 week and resulted in no significant change to the nozzle mount.

Chamber Seal Testing

The nozzle mount was subjected to a week long test where the salt spray was ran with water and air at 95F, creating a fog. The “fog“ did not escape to the surroundings or inside the chamber.