Goal:

Analyze the force of pulling a brake cable that actuates the rubber pad in order to stop a bicycle wheel with a u-brake. Thus, anticipating how the assembly behaves.

Skills:

Modeling

Material Selection

FEA Analysis

Understanding of stress

Fixtures

Interpreting Data

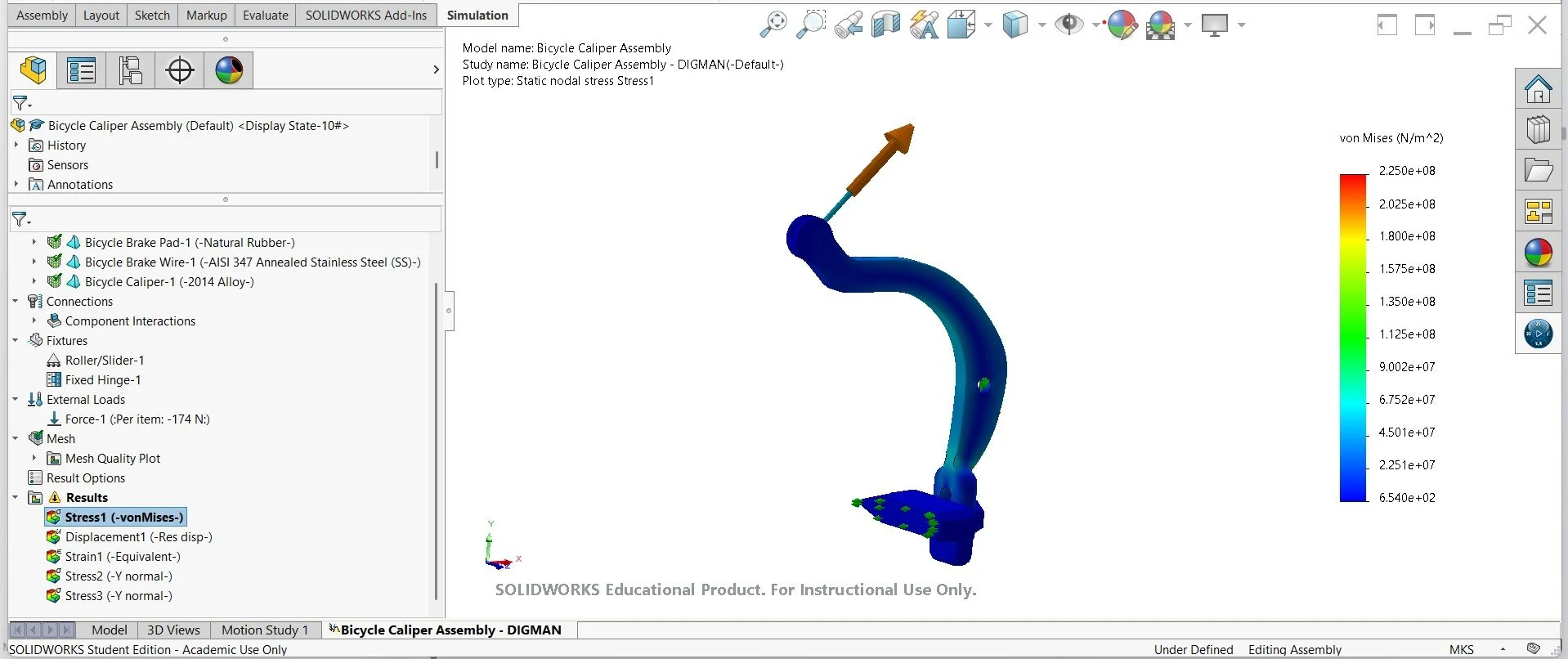

Von Mises

Results:

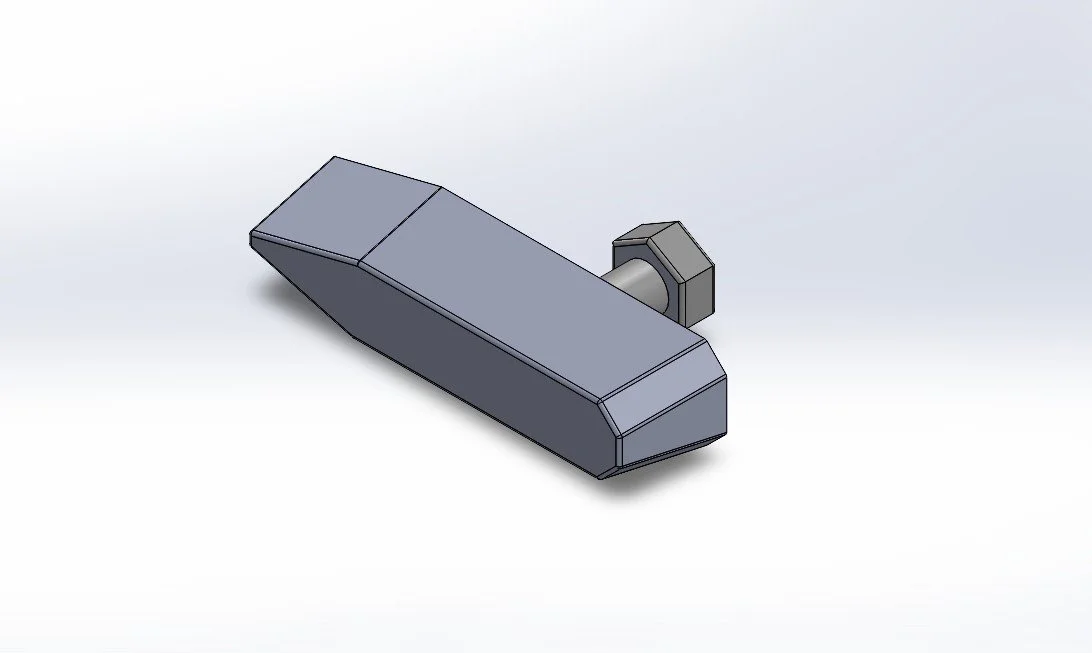

Von Mises will take a more wholistic look at the combined stresses occurring on the U-brake when a 174N force is perpendicular to the cable slot and notify of yielding likelihood at certain locations. The material is 2014 aluminum alloy with a yield strength (Sy) of 9.65098×10⁷ N/m² in the simulation. The max Von Mises stress value is 2.25×10⁸ N/m². Comparing the yield strength and the maximum Von Mises value, the part is likely to yield and not return to its original shape. The minimum value of 6.54×10⁸ N/m² is not of great concern and appears to be on the bolt holding the pad to the U-brake arm. Because of the brake deformation, the brake should be replaced if there is a cable force that meets or exceeds 174N. A greater yield strength would add more rigidity to the assembly and help resist changes in dimensions. Switching the material to a stronger metal would aide in this effort, but may increase weight.

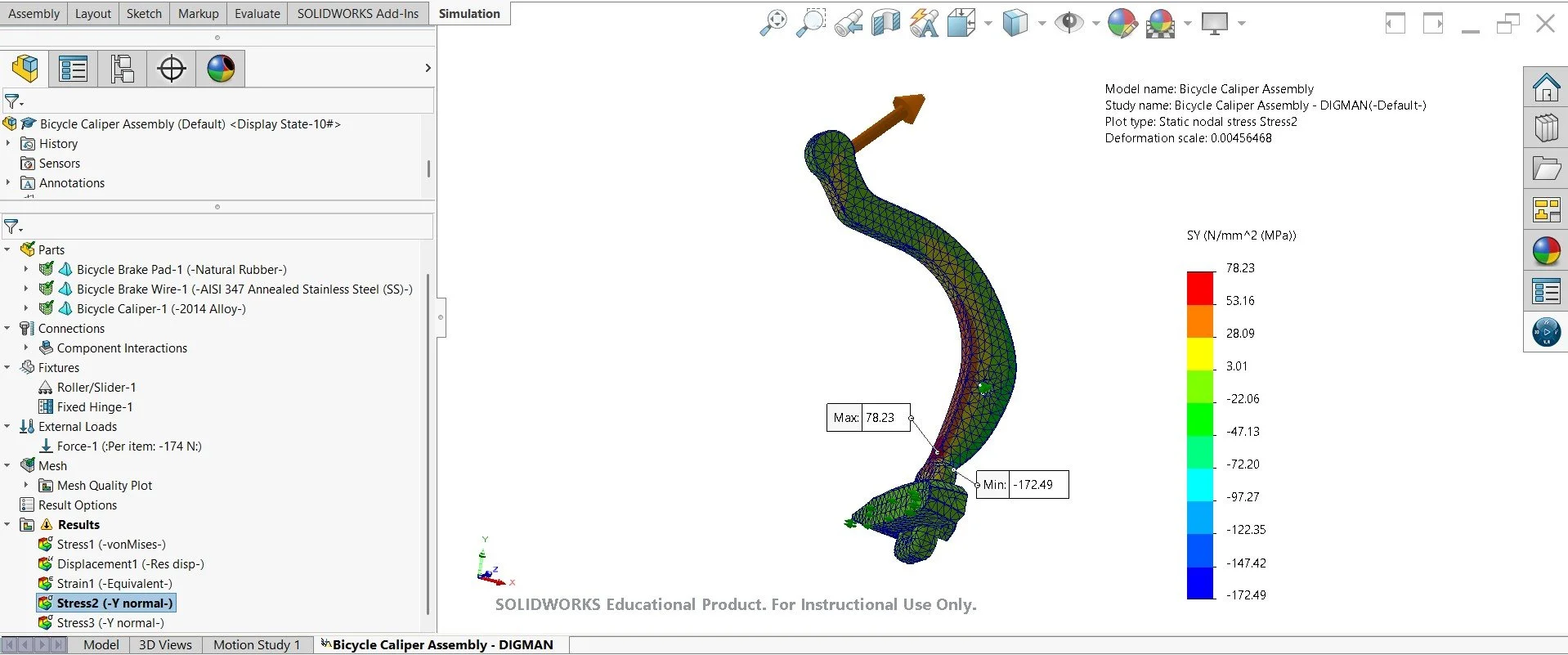

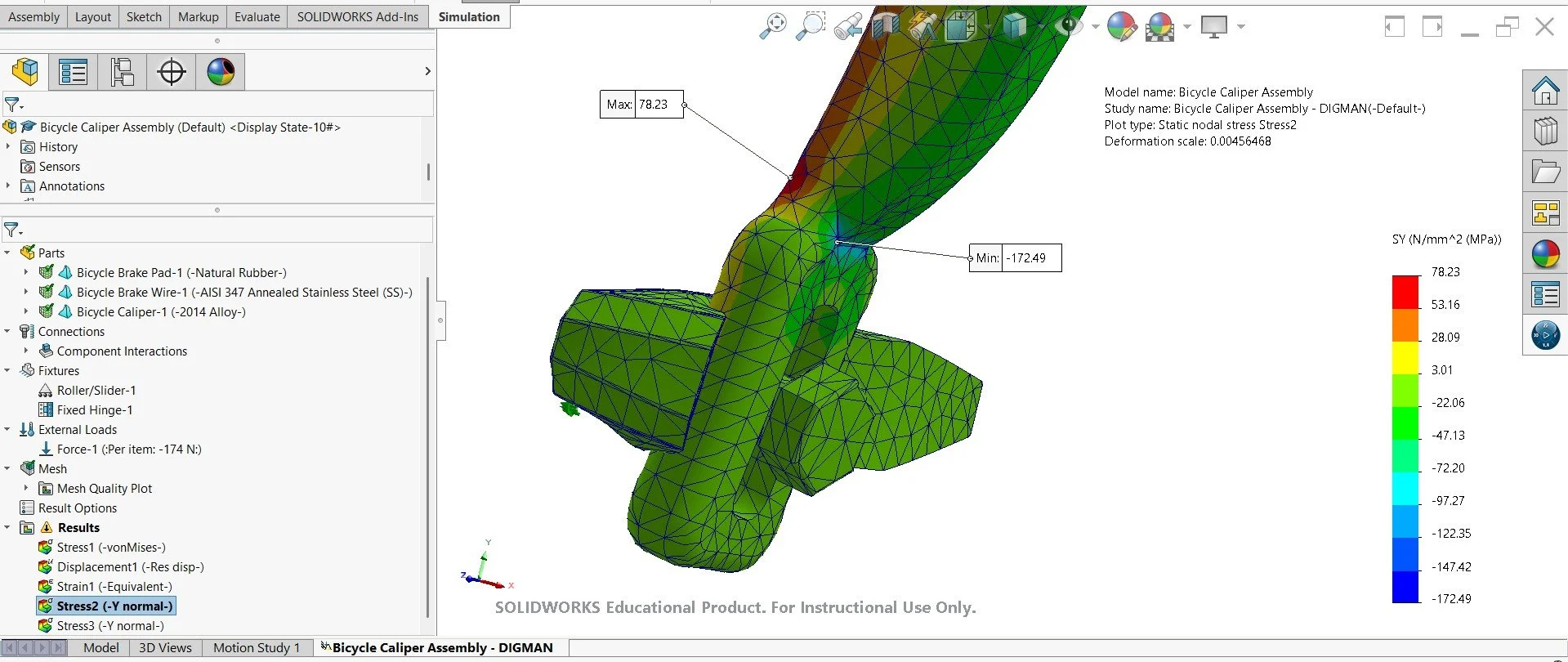

Compression

Results:

The interior of the U-Brake arm receives a maximum compressive yield of 172.49 MPa with a normal “pulling” force of 174N at the cable. This negative stress value reflects compression, at a greater value than in max tension. So after this value the part is likely to not return to its original shape, affecting intended braking performance. Because the direction of the yielded part now putting the brake pad further from the wheel, the brake may not come into contact with the wheel. This affected part however in a real life scenario should be replaced for accurate braking by the rider.

Tension

Results:

The interior of the U-Brake arm receives a maximum tensile yield of 78.23 MPa with a normal “pulling” force of 174N at the cable. So after this value the part is likely to not return to its original shape, affecting braking performance. Because the direction of the yielded part, the possibility of the deformed part may interact with the physical wheel creating safety concern.

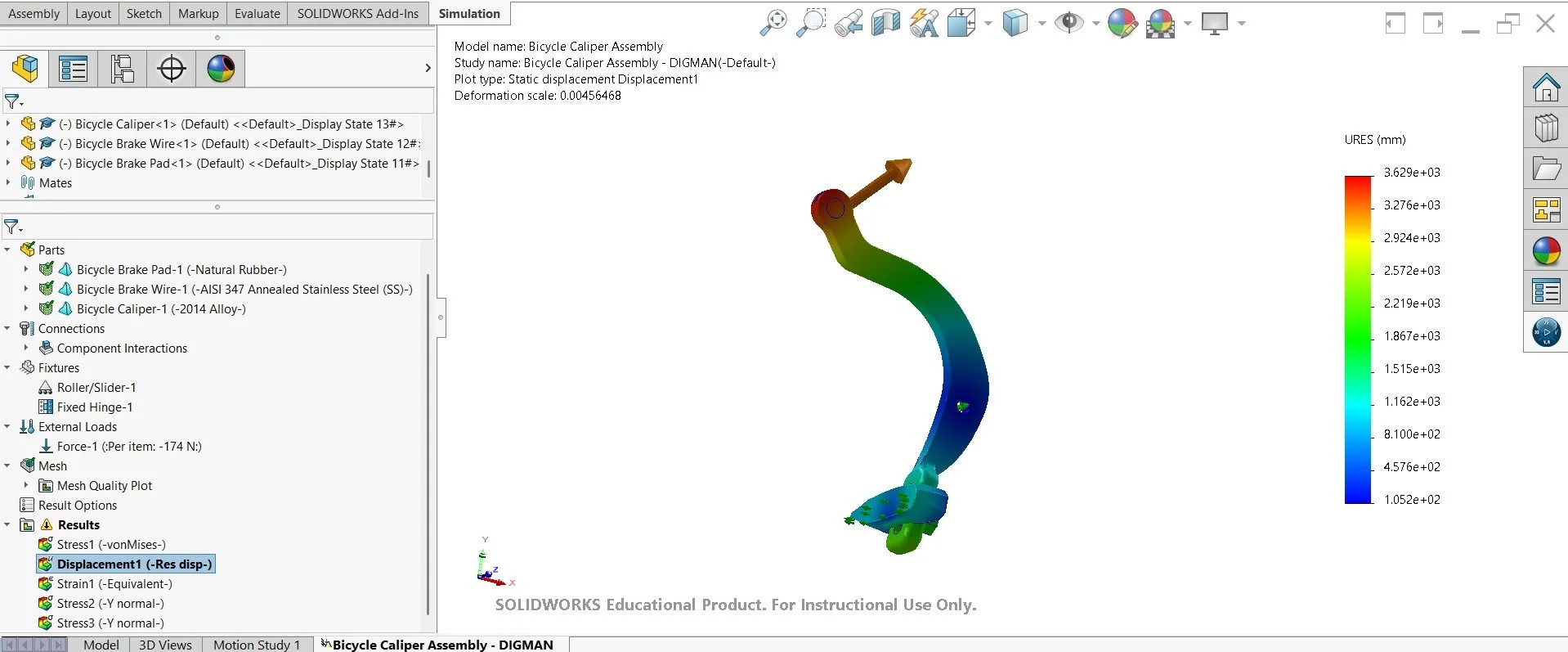

Displacement

Results:

Most of the displacement is close to the location of the cable “pulling” force. Obviously, displacement does not point to direct failure of the part. However, where the part is likely to move to in this scenario is unlikely to bring great danger to the rider. Where the displacement occurs is above the tire and being pulled against a path that would not interfere with the tire.